Pipeline dimensioning for steam-water

| Pipeline dimensioning for a heat transfer station | |||||||||

| Saturated steam - water | |||||||||

| Primary side | p1 must be >=1,6 and p1<=70 |

Secondary side | |||||||

| Steam Pressure p1: | bar A | p01 given (option) | Supply temp.: | °C | |||||

| Steam Pressure p01: | bar A | bar A | Return temp.: | °C | |||||

| Saturated steam temp.: | °C | p01 must be >=1,1 and <p1 |

The supply temp. must be greater than the return temp. |

||||||

| Steam quantity (m): | kg/h | ||||||||

| Pressure drop: | bar | The supply temp. must be less than the saturated steam temp. |

|||||||

| Velocity: | m/s | ||||||||

| Heat capacity in kW: | |||||||||

| DN | mm | ||||||||

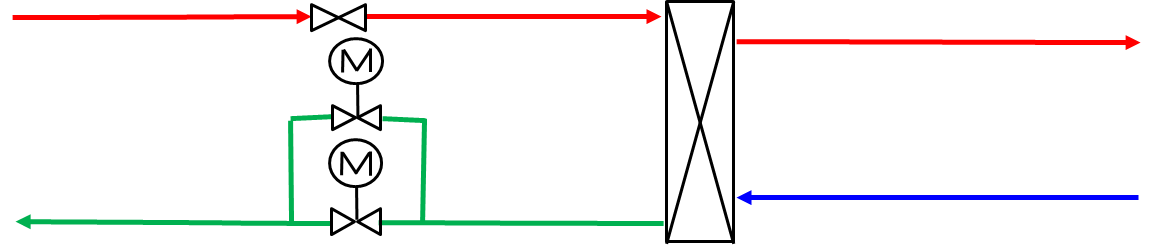

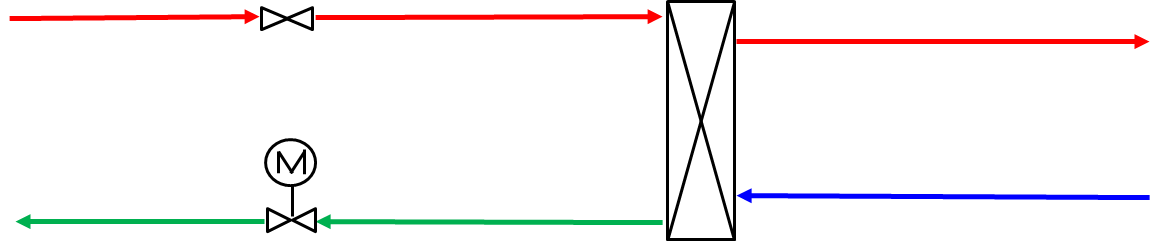

01 | Heat exchanger | ||||||||

| °C04 | |||||||||

| p1 | p01 | ||||||||

| bar A | bar A | Quantity [m³/h]: | |||||||

| °C saturated steam | Quantity [l/s]: | ||||||||

| Quantity [l/min]: | |||||||||

bar A | |||||||||

at the outlet | |||||||||

| °C03 | |||||||||

| 02 | °C | ||||||||

The condensate temp. must be greater than the return temp. |

Pressure drop: | bar |

|||||||

| Condensate temp.: | °C | Number of condensate valves: 1 | Velocity: | m/s | |||||

The condensate temp. must be <= the saturated steam temp. |

|||||||||

| DN | mm | ||||||||

Pressure drop: | bar |

||||||||

| Velocity: | m/s | ||||||||

| DN | mm | ||||||||

| Calculation of pressure drops | |||||||

| Please enter the KVS values of the valves in the gray fields. | |||||||

| Pipe section 01 | |||||||

Please enter a real KVS value depending on the selected nominal diameter | |||||||

| Description | KVS | Pressure drop | |||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

The pressure drop must not be greater than the available pressure | |||||||

| bar pressure drop of pipe section 01 | |||||||

| barA steam pressure applied to the heat exchanger (p01) | |||||||

| Pipe section 02 | |||||||

Please enter a real KVS value depending on the selected nominal diameter | |||||||

| Pressure drop | |||||||

| Pressure drop of the heat exchanger on primary side | bar | ||||||

| Description | KVS | ||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

The pressure drop must not be greater than the available pressure | |||||||

bar pressure drop of condensate line + heat exchanger (pipe section 02 + WT) | |||||||

bar total pressure drop on primary side (pipe sections 01+02) | |||||||

barA condensate pressure applied to the end of the condensate pipeline | |||||||

The pressure drop must not be greater than the available pressure | |||||||

| Pressure drops pipe sections 03/04 | |||||||

Please enter a real KVS value depending on the selected nominal diameter | |||||||

| Pressure drop | |||||||

| Pressure drop of the heat exchanger on secondary side | bar | ||||||

| Description | KVS | ||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

| bar | |||||||

bar total pressure drop of pipe sections 03/04 | |||||||