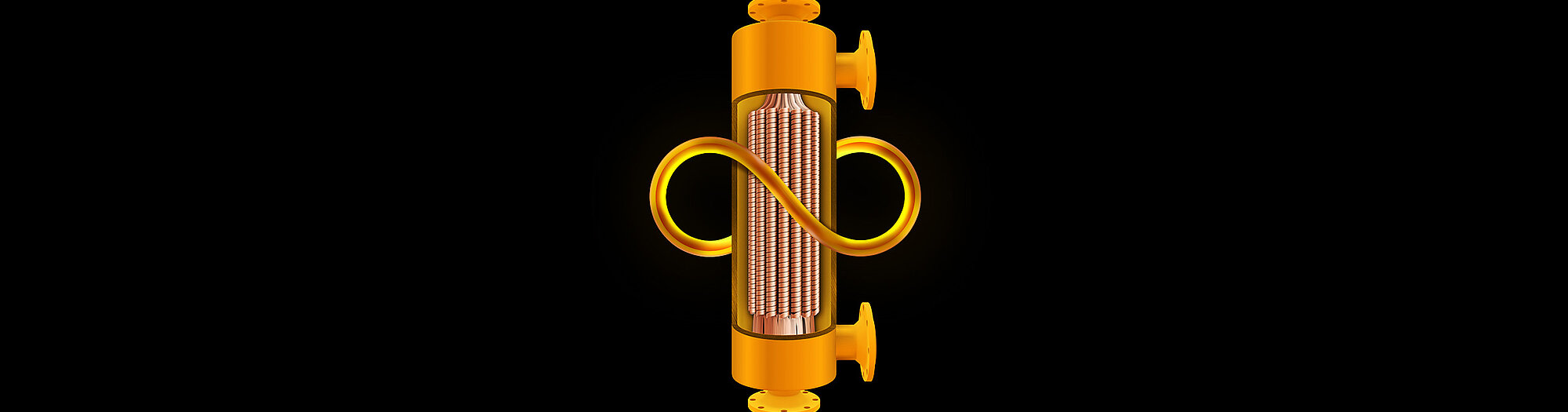

Heat exchanger Modulo

At a height of around 900 mm and weighing in at max. 20 kg per module, these single material heat exchangers offer high performance despite their compact size. The use of steam manifolds means that modules can easily be exchanged, added or removed, enabling a flexible load capacity and minimizing downtime.

Advantages of the modular technique

- Lightweight and compact design

- Lower consumption of primary energy due to especially low heat loss

- Better part load adaptation

- Quick exchange of individual modules, e.g. for cleaning purposes, makes for optimal availability of the installation

Finned tube heat exchanger baelz 147

Finned tube heat exchanger Modulo for integration into modular transfer stations. Ideal for hot water heating, domestic water heating, cooling, production facilities, drinking water. The self-cleaning effect inhibits deposits.

| Technical data | Tube side | Shell side | Materials |

|---|---|---|---|

With clarinets Finned coiled tubes | Steam / water | Water | Entirely in copper |